The wear layer consists of a special cellulose paper treated with synthetic resin as the durable surface of the flooring. Laminate is fundamentally composed of several layers.

The decor layer gives the laminate.

Composition of laminate flooring. The laminate floor board is made up of several layers. It is unlikely to fade in sunlight. Laminate flooring also called floating wood tile in the united states is a multi layer synthetic flooring product fused together with a lamination process.

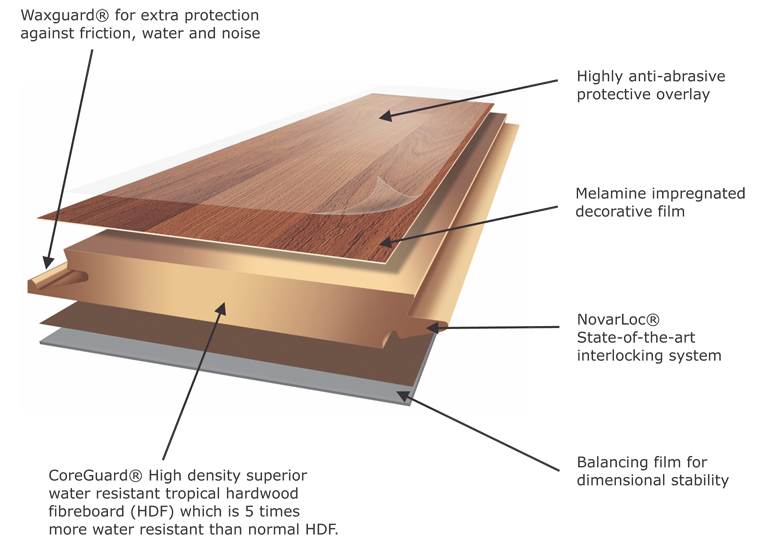

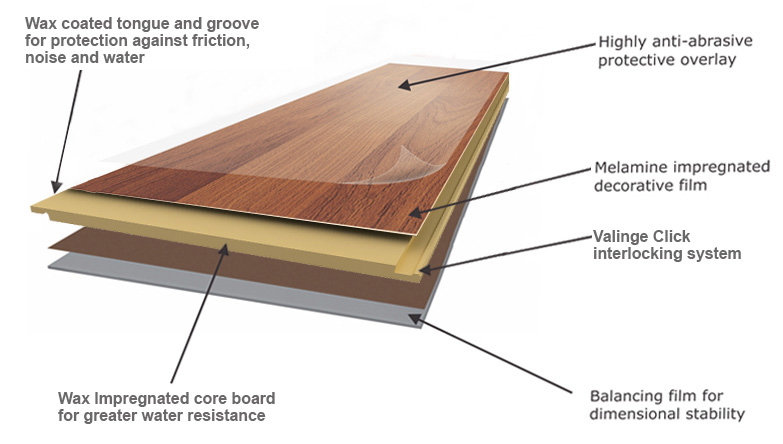

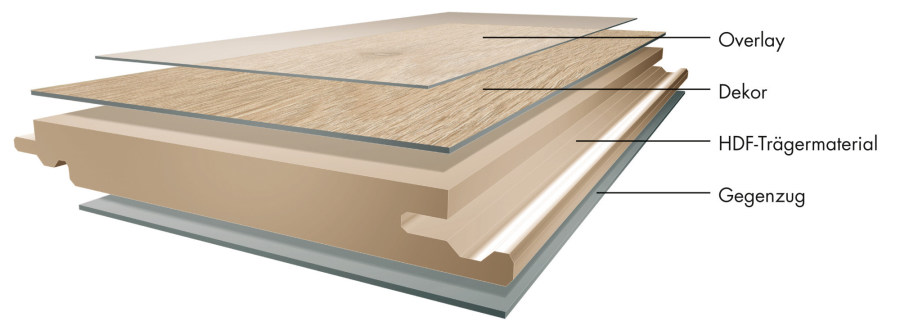

First there is the upper wear layer and a decor layer with one or several layers depending on the production method used. Laminate floor board structure and composition. The plank materials finish thicknesses and edge geometry all differ.

Sheets of laminate flooring are made by fusing these four layers together at over 600 pounds of pressure per inch at temperatures of around 400 degrees fahrenheit. Hardwood is a natural product. Correctly installed laminate flooring with tight seams and good baseboards or moldings can tolerate pooled water but only a short period of time.

First the uppermost laminate layer consists of an overlay to protect against wear and tear and a design layer which depending on the production process is made from one or several layers. Composition of laminate flooring. One of the most obvious differences between hardwood and laminate flooring is the composition.

Both linoleum and a quality laminate floor can last for decades with proper care yet the two materials are completely different. For family bathrooms or other areas where standing water is likely laminate flooring is a poor choice. In the direct pressure laminate process the decorative covering layer and stabilizing layer are pressed together onto the core layer.

Laminate flooring simulates wood or sometimes stone with a photographic applique layer under a clear protective layer. Laminate flooring is a high quality image of wood fused to a fiberboard core and topped with a highly durable transparent wear layer. Good laminate flooring is less prone to some of the problems that plague hardwood.

Usually the top layer in a laminate floors composition will help protect it from nicks and scratches and its water resistant layers mean it is appropriate for kitchens and bathrooms in a way that hardwood is not. Evoke vcc thats vinyl composite core combines the very best features of both laminate and luxury vinyl. Laminate flooring manufacturers have responded to the competition from engineered wood and have stepped up their game with newer iterations that not only look even more like wood but feel like it.

Composition of a direct pressure laminate floor. Laminate flooring manufacturers often state that the product is water resistant. The inner core layer is usually composed of melamine resin and fiber board materials.

Linoleum is a composite made from linseed oil and chips and powders from wood and plant matter while laminate is made from layers of materials pressed together. The boards are rigid planks with a click together joint system like laminate but theyre constructed from a waterproof vinyl composite material which gives them the install it anywhere flexibility of vinyl flooring.

Non Slip Coating Floor Grip By Slipdoctors Gloss Clear Roll On High Traction Non Slip Sealer Barefoot Paw Friendly Easy Application

Non Slip Coating Floor Grip By Slipdoctors Gloss Clear Roll On High Traction Non Slip Sealer Barefoot Paw Friendly Easy Application

The Construction Layers Of High End Resilient Flooring Herf

Wood Plastic Composition Wpc Vinyl Plank Flooring Tile

Wood Plastic Composition Wpc Vinyl Plank Flooring Tile

Prime Flooring Pattern Patterns In Vinyl Composition Tile

Installation Training Armstrong Flooring Commercial

Installation Training Armstrong Flooring Commercial

Vinyl Composition Tile Flooring Living Room Plank Kitchen

Vinyl Composition Tile Flooring Living Room Plank Kitchen

Installation Instructions Finfloor Inovar Floor

Installation Instructions Finfloor Inovar Floor

Authentic Herringbone Laminate Flooring Laminates Finfloor

Authentic Herringbone Laminate Flooring Laminates Finfloor

Vinyl Composition Tile Laminate Flooring Slate Floor 700

Vinyl Composition Tile Laminate Flooring Slate Floor 700

China Wood Bamboo Composition Flooring Most Popular

China Wood Bamboo Composition Flooring Most Popular

Composition Of Laminate Laminate Floor Layers Hdf Dpl

Composition Of Laminate Laminate Floor Layers Hdf Dpl

A Brief Guideline About Engineered Hardwood Vs Laminate By

A Brief Guideline About Engineered Hardwood Vs Laminate By

Na 1 Na 15 2 0mm Vinyl Composition Tile 15 Natuline Colors Tajima Flooring Free Sample Available Buy Flooring Product On Alibaba Com

Na 1 Na 15 2 0mm Vinyl Composition Tile 15 Natuline Colors Tajima Flooring Free Sample Available Buy Flooring Product On Alibaba Com